From Classroom Sketch to Precision Machine

It all started with a simple sketch born out of boredom in a school lesson. The initial version of my automated cocktail mixer was a testament to resourcefulness, constructed from wood and parts sourced from Amazon and a local hardware store. This first prototype, while basic, laid the groundwork for what was to come.

The project took a significant leap forward with the acquisition of a 3D printer. This new tool allowed for a complete redesign, moving from a rustic wooden frame to a precisely printed structure. The upgrade wasn't just aesthetic – I integrated peristaltic pumps and flow sensors to meticulously control the liquid volumes, perfecting the mixing ratios for each cocktail. The original LCD was replaced with a more intuitive touch display, enhancing the user interface and overall experience.

What began as a simple hobby project evolved into a sophisticated device, showcasing a journey of learning and a passion for technology.

It all started with a simple sketch born out of boredom in a school lesson. The initial version of my automated cocktail mixer was a testament to resourcefulness, constructed from wood and parts sourced from Amazon and a local hardware store. This first prototype, while basic, laid the groundwork for what was to come.

The project took a significant leap forward with the acquisition of a 3D printer. This new tool allowed for a complete redesign, moving from a rustic wooden frame to a precisely printed structure. The upgrade wasn't just aesthetic – I integrated peristaltic pumps and flow sensors to meticulously control the liquid volumes, perfecting the mixing ratios for each cocktail. The original LCD was replaced with a more intuitive touch display, enhancing the user interface and overall experience.

What began as a simple hobby project evolved into a sophisticated device, showcasing a journey of learning and a passion for technology.

Project Evolution Timeline

Phase 1: Wooden Prototype

Initial design using basic materials: wood frame, simple pumps, basic LCD display.

Proof of concept built with Amazon components and hardware store materials.

Phase 2: 3D Printed Redesign

Complete structural overhaul using 3D printing technology. Enhanced precision,

improved aesthetics, and better component integration.

Phase 3: Advanced Control System

Integration of peristaltic pumps, flow sensors, and touch display interface.

Precise volume control and enhanced user experience.

Technical Specifications

Pump Type:

Peristaltic

Volume Control:

Flow Sensors

Interface:

Touch Display

Construction:

3D Printed

Control Board:

Arduino Compatible

Liquid Lines:

Multiple Channels

Project Gallery

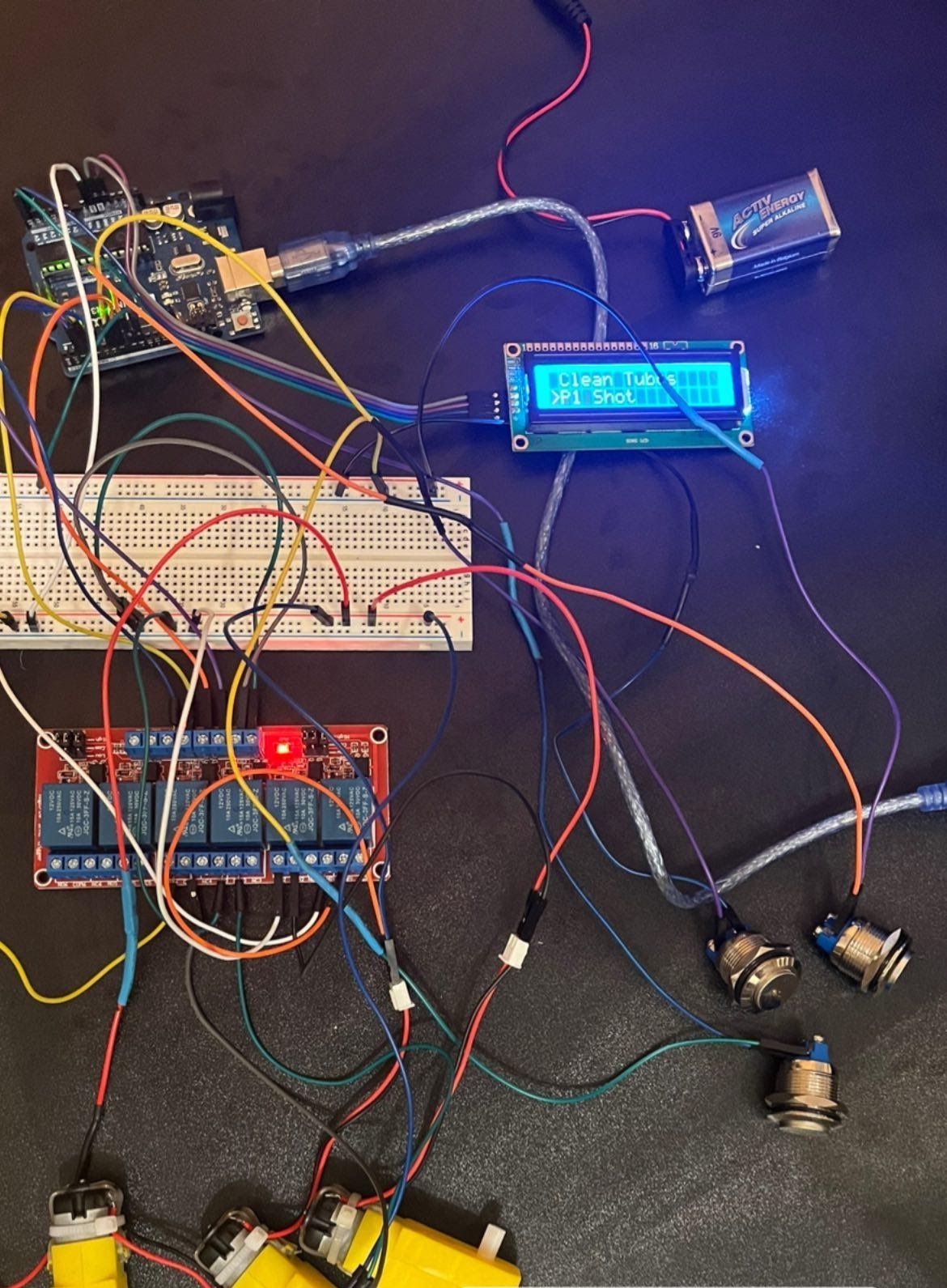

prototype_v1_electronics.jpg

Early electronics prototype featuring Arduino, relay board, LCD display, and breadboard connections.

This represents the initial control system before the 3D printed enclosure.

wooden_prototype_v1.jpg

Original wooden prototype showing the basic frame structure and early pump system.

Built with materials from local hardware store, demonstrating resourceful engineering approach.

final_3d_printed_version.jpg

Final 3D printed version featuring sleek red and black design, touch display interface,

and integrated pump system. Shows the dramatic evolution from wooden prototype to professional-grade device.

3d_design_renders.jpg

CAD design renders showing multiple views of the 3D printed enclosure.

Demonstrates the engineering process from concept to final design with precise component placement.

operation_demo.mp4

Live demonstration of the cocktail mixer in operation, showing the user interface,

pump activation, and precision liquid dispensing system in action.

Key Features

• Precise Volume Control: Peristaltic pumps combined with flow sensors ensure accurate liquid measurements for consistent cocktail ratios.

• Intuitive Interface: Touch display replaced the basic LCD, providing a modern and user-friendly control system.

• Professional Design: 3D printed enclosure offers both aesthetic appeal and functional component organization.

• Modular System: Multiple liquid channels allow for complex cocktail recipes and ingredient combinations.

• Educational Value: Project demonstrates integration of mechanical design, electronics, and software programming.

• Intuitive Interface: Touch display replaced the basic LCD, providing a modern and user-friendly control system.

• Professional Design: 3D printed enclosure offers both aesthetic appeal and functional component organization.

• Modular System: Multiple liquid channels allow for complex cocktail recipes and ingredient combinations.

• Educational Value: Project demonstrates integration of mechanical design, electronics, and software programming.

Technologies Used

3D Printing:

Custom Enclosure Design

Microcontroller:

Arduino Platform

CAD Design:

Autodesk Fusion 360

Programming:

C++ (Arduino IDE)

Electronics:

Relay Control, Sensors

Materials:

PLA, Wood, Electronics